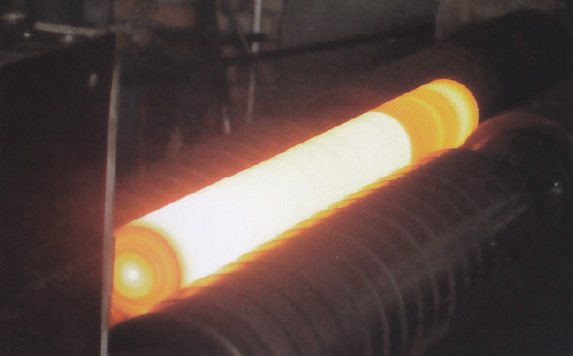

Nitriding treatment

The hardness of the machine barrel screw after nitriding treatment can reach over hv900. The products after nitriding treatment have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance.

Nitriding hardness: HV ≥ 900

Nitriding depth: 0.5-0.6mm